The sublimination process is captured with the Thermo Scientific Helios 5 UX and the MicroReactor. Video courtesy of the PNNL/Sara Levine

A new study published in Nature Energy has revealed that a common lithium salt may serve as a critical ingredient to manufacture cheaper, longer-lasting battery materials. The discovery centers on sublimation, the process whereby a solid turns directly into a vapor.

Scientists at the U.S. Department of Energy’s Pacific Northwest National Laboratory (PNNL), in collaboration with Thermo Fisher Scientific, have showed that vapor from lithium oxide (Li2O) sublimation accelerates a chemical reaction that forms single crystals when mixed with nickel-rich precursors.

Single-crystal battery materials are thought to help batteries last longer. What’s more, the sublimation happens at just one atmosphere of pressure, the everyday pressure felt at sea level.

“The discovery offers a potentially faster, more efficient, and cheaper way to scale up the manufacturing of nickel-rich lithium-ion batteries,” said Jie Xiao, co-author on the paper and a Battelle Fellow who holds a joint appointment with PNNL and the University of Washington. “The research shows us how materials science can be applied to simplify the manufacturing process.”

The promise of nickel

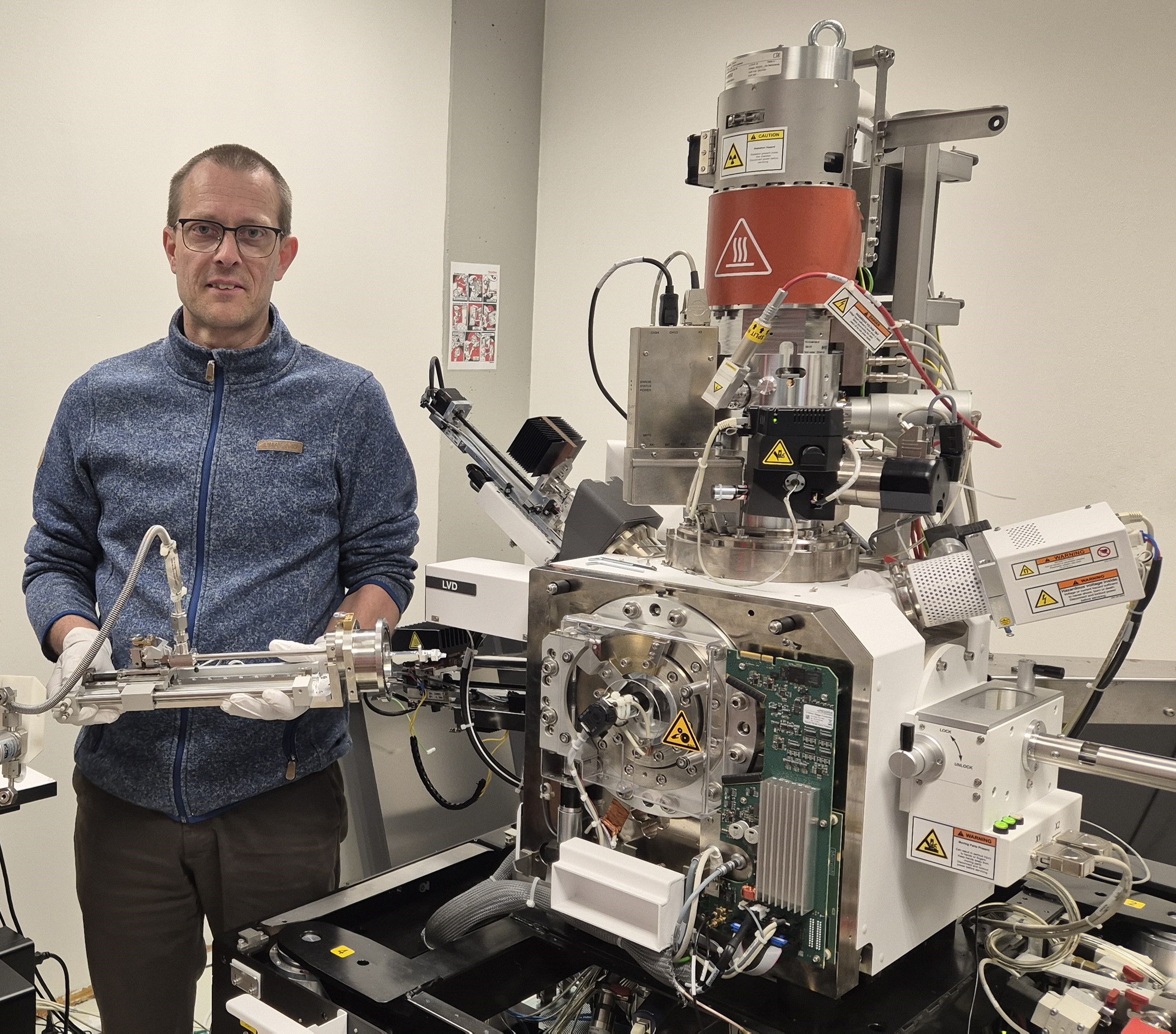

Libor Novák, Ph.D., R&D manager at Thermo Fisher, is pictured holding the MicroReactor next to a scanning electron microscope.

Libor Novák, Ph.D., R&D manager at Thermo Fisher, is pictured holding the MicroReactor next to a scanning electron microscope.

Boundaries between the crystals—like the boundary between the cookie and the chocolate chips—become weaker as the battery discharges and charges. Over time, these weaknesses lead to cracking, which degrades the battery and shortens its lifetime. In the past five years, Xiao and her colleagues have been searching for materials that form single-crystal structures, like a plain chocolate cookie. The chocolate is still there, but it’s evenly distributed through the cookie rather than packed in clumps.

The mystery of sublimation

Xiao’s team has been exploring different lithium salts. Mixing these salt ingredients with nickel-rich precursors produces cathode material. One of the most common production methods is to melt the lithium salt, which then reacts with the nickel-rich precursor. For this process, researchers have preferred lithium hydroxide (LiOH) because it has a low melting point.

Jie Xiao, co-author of the study published in Nature Energy.

Jie Xiao, co-author of the study published in Nature Energy.

“It was a very exciting moment during the experiment when we were able to not only record the reaction in real time, but to also confirm that the process may serve as a new approach to development more efficient and cost-effective batteries that are in very high demand globally,” said Libor Novák, Ph.D., research and development manager for the analytical instruments business at Thermo Fisher and inventor of the MicroReactor.

The new research confirms the mechanism is driven by Li2O sublimation. In the baking scenario, it would be like combining the cookie dough with vaporized chocolate. The cookie has no chunks of chocolate, just a chocolate cookie with no distinct boundaries.

“The vapor can penetrate everywhere, right into the other precursors’ pores or surface and immediately react,” Xiao said. “Single crystals form much faster in the presence of those vapors.”

Potential boon to manufacturing

The discovery may provide a new way to manufacture single crystals, but the team has more work to do to make the process more cost effective. With industry partners, Xiao and her team are now working to scale up the process with lower manufacturing costs.

The team hopes to provide single crystals to their strategic partners in 2026.

This work was funded by the Advanced Materials and Manufacturing Technologies Office and the Vehicle Technologies Office within the Department of Energy’s Energy Efficiency and Renewable Energy Office.